Finding the Perfect (Fake) Leather

We invested quite some effort in finding the perfect material for Axel's jacket, an endeavor that unfortunately led to a delay.

For the first time on our backstage blog, we're diving into some issues that have held up our production. We also want to take this opportunity to peel back the curtain a bit more on our production process.

Many of you might have found your way here because of our recent delay notice for the Axel Plush. To be honest, those who've been with us for a while probably aren't shocked by a pre-order delay. It's not something we're proud of, but here backstage, we prefer to skip the usual business apologies and instead focus on the reasons and experiences behind the issue.

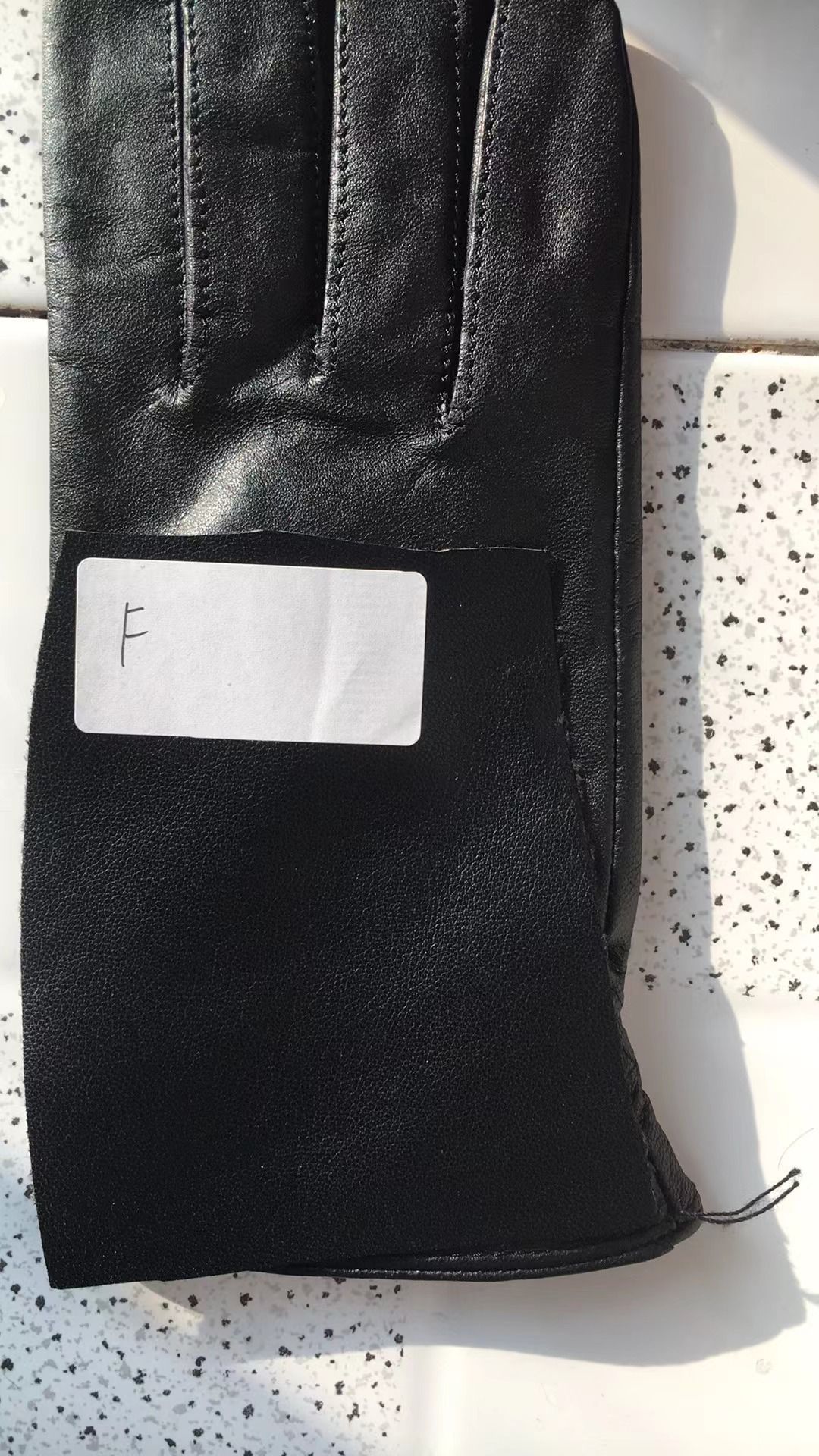

Axel is our first plush to feature a leather outfit, whereas previously, we only used leather for accessories like belts. So, we're giving extra care to every detail of his jacket. Since we prototype in Korea and manufacture in China, finding the exact same materials is often a challenge, but we always strive for the perfect match. This time around, it took quite a bit of time, but we managed to get our samples by the end of December.

It's important to note that when we talk about leather here, we're referring to polyurethane (PU) leather. We're in the process of phasing out all animal products, and our commitment to not using genuine leather is a part of this initiative. However, working with PU leather presents its own set of challenges. Unlike genuine leather, whose mechanical properties are fairly consistent, PU leather qualities can vary significantly across the market.

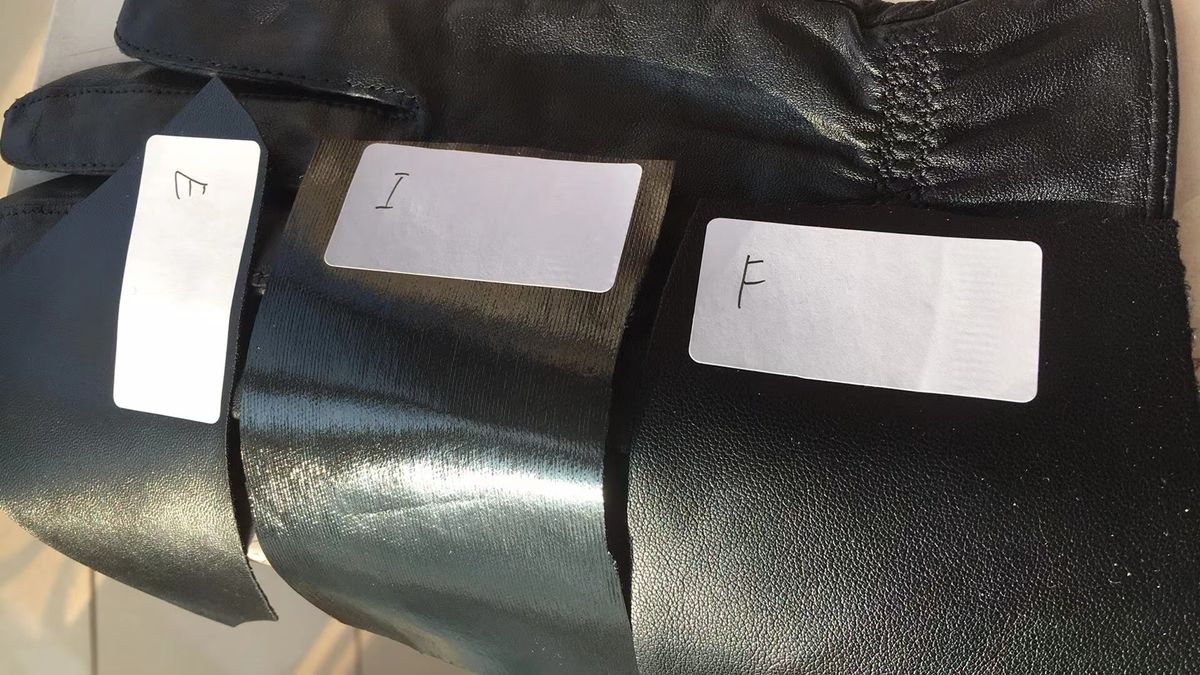

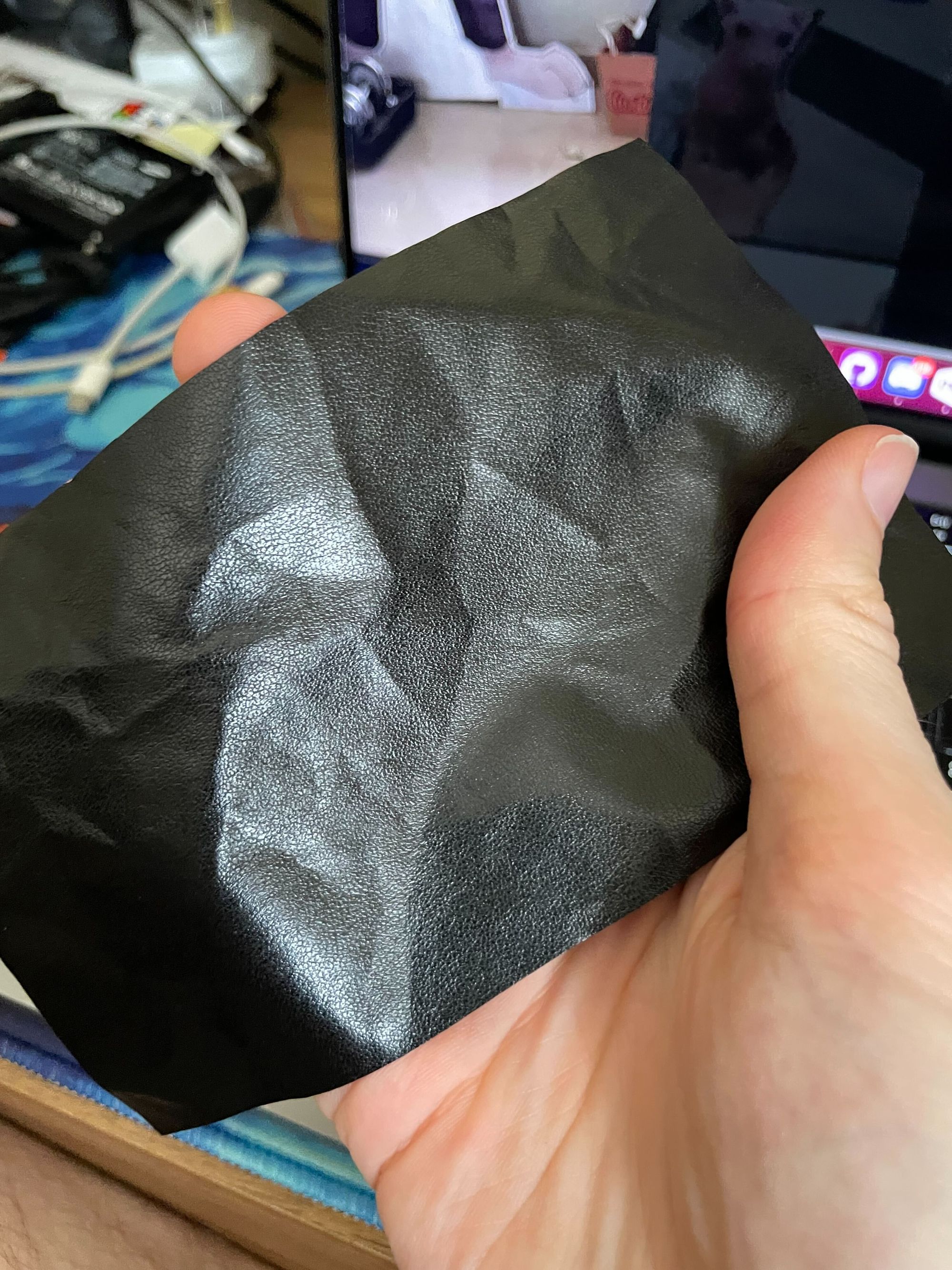

The problem with the initial leather sample was that it was too rigid, making it prone to creasing easily—similar to how paper creases. Although it does recover over time with some rubbing, we were concerned this leather would not look good in production. Ultimately, we decided to reject this material.

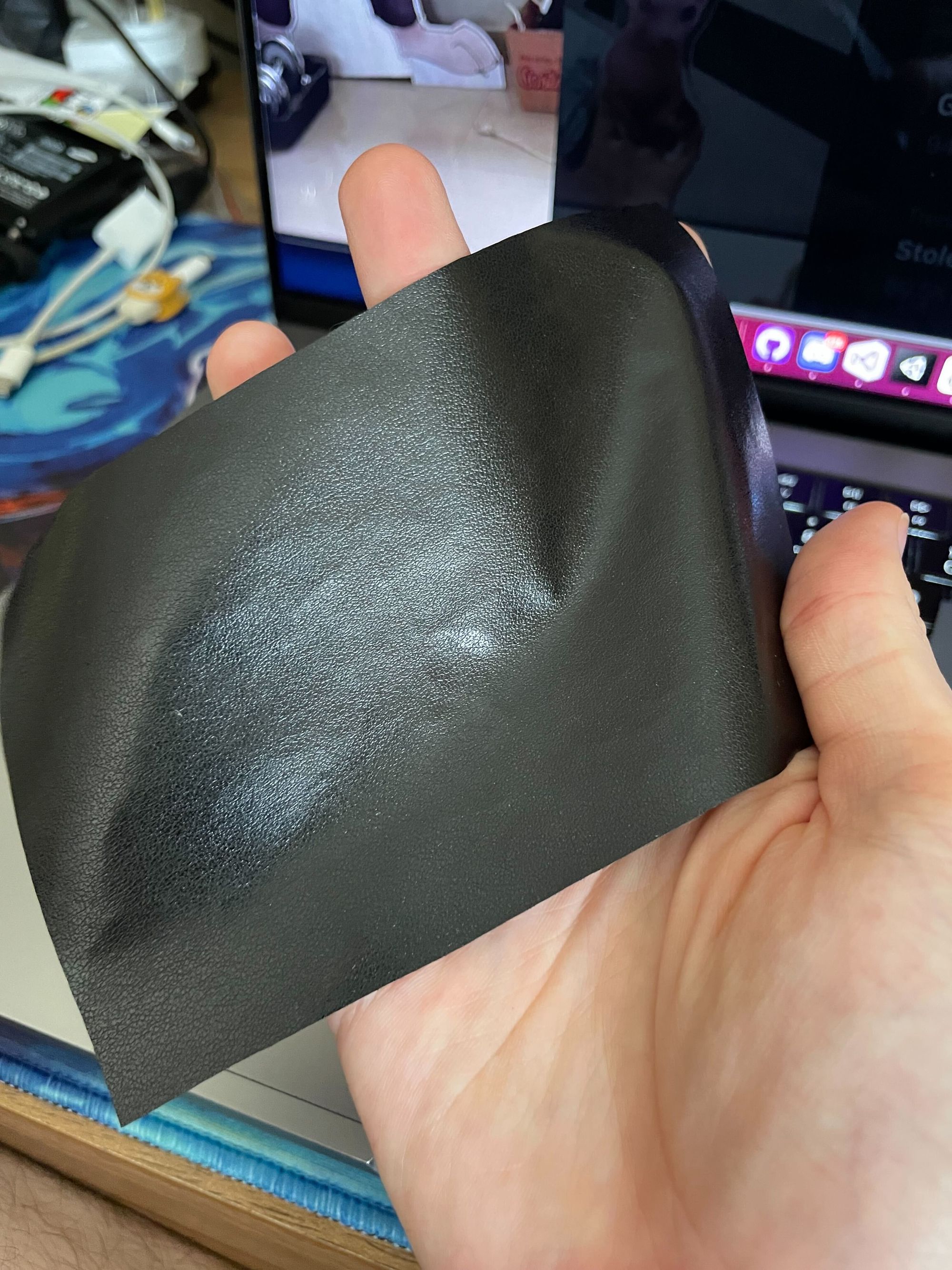

This decision meant it was impossible to finish production before March, especially since all of February is a no-go in China due to the Spring Festival. However, during this time, we did find a suitable leather, one that's soft enough to rival a lambskin glove.

With the material hunt for Axel finally over, we're all set to kick things into gear as soon as the factory resumes operations. We're excited to share this update with you and look forward to sharing more stories from the production side in the future (hopefully without any delays).